South Asia Product Team 2019 DEC BLOG | PRIVACY POLICY | LEGAL| MY STRATASYS

Update for December 2019

What's new?

1. Stratasys Academy Reminder

2. Toolkit

3. A Clear Winner

4. Technology Eases Pain

5. Partner Meeting 2020

6. Flattening the Learning Curve

7. This Month's Announcements

8. A New Hot Application

FINISH YOUR QUIZ

Click below to finish the H2 NPI Quiz

REPORT LOGIN ISSUES

Don't hesitate to report, we will response quickly

CONTACT US

Send us an email, tell us everything

|

|

|

|

Toolkit

|

|

Two case studies and one video become available this month. i-Tork Controls, a Korean company that specializes in designing and manufacturing actuators, is using Objet30 Pro to simplify its prototyping process; hoping to shorten the operation and the lessen the pains that his patients feel, Dr. Gong, a Chinese doctor, starts to perform surgeries with patient–specific guide plates 3D printed with Stratasys’ F450; Fusetec, based in Adelaide, Australia, makes use of the newly released DAP to make hyperrealistic medical models that promise to disrupt a $7.6 trillion global industry.

The case studies and video are all in English; for local-language version, please reach out to your respective regional marketing leader.

Good selling!

|

|

|

|

“In general, it costs approximately KRW 1.5 million ($1,240) to outsource the production of a gearbox prototype. With the Stratasys Objet30 Pro, the maximum cost is KRW 400,000 ($330).”

Park Gyeon-seon

i-Tork Controls

A Clear Winner

|

|

Founded in 1999, i-Tork Controls specializes in designing and producing high-quality electric and pneumatic actuators. To continue expanding both domestically and internationally, i-Tork needed to improve manufacturing efficiency. One of the manufacturing steps that consumed too much time was creating prototypes for new products, which was originally done via CNC machining. A whole month often passed before the first prototype was presented to the R&D department.

Click here to find out how i-Tork Controls solves its prototyping problems with PolyJet™ technology.

Technology Eases Pain

|

|

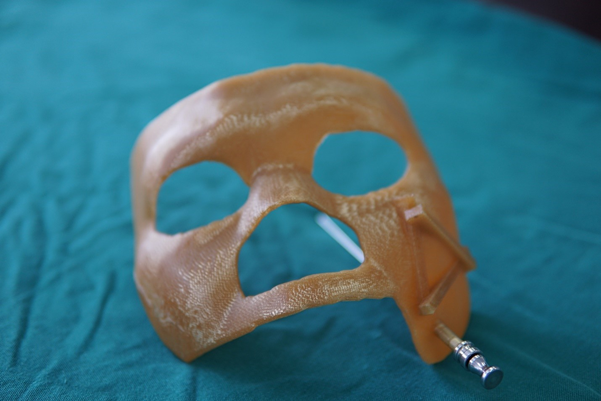

Dr. Gong, at the Third Affiliated Hospital, Sun Yat-Sen University, is an expert in the treatment of trigeminal neuralgia. He typically performs percutaneous micro balloon compression, a procedure in which nerve fibers are damaged to block the pain. Inspired by other 3D printing surgical applications, Dr. Gong set out to develop patient–specific guide plates to navigate the route to the oval foramen. To assist him, Dr. Gong consulted Klein Wang, application engineer at Stratasys who specializes in medical solutions.

Click here to find out how doctors use 3D printed guide plate simplifies trigeminal neuralgia surgery.

“It is simply amazing how this new technology is helping with medical solutions.”

Dr. Gong

Third Affiliated Hospital Sun Yat-Sen University

IMPACT 2020

Big Announcement: Global Partner Meeting Impact 2020

|

|

Stratasys’ most important event is just around the corner! Our 2020 global partner kickoff meeting will take place on January 21-24, 2020 at Sawgrass Marriott Golf Resort & Spa, located in Ponte Vedra Beach, Florida.In 2020, Stratasys will be releasing a number of exciting new products; to celebrate, and plan for a great year ahead, we invite all our partners from around the globe together.

At this annual meeting, Stratasys executives will provide updates on 2020 GTM alignment, and you will receive a hands-on training on the 2020 NPI. We’ll have specific marketing, sales, and technical breakout sessions in addition to the general sessions and technology showcases open to all attendees.

There will also be ample opportunities for you to network with peers from around the world and learn from one another regarding business strategies. Or, you can simply make more friends.

Nothing prepares you better for a fruitful new year than a couple of fulfilled and restful days in the sun-kissed Florida! Please make sure that you are properly registered here and book your flights early. Additionally, now is also a good time to schedule with Stratasys managers and regional peers in advance.

See you in Florida!

|

|

Flattening the Learning Curve

|

|

Cadavers are very expensive: to acquire, transports, store, maintain and later disposal also adds a lot of costs. They are rare, and difficult to obtain in developing countries. This means that students cannot get enough hands-on training; most of the time, they are passive observers. Practice makes perfect, but what if you don’t get to practice? Furthermore, pathologies cannot be ordered: you get what you get. With Stratasys’ DAP (J750™ Digital Anatomy™ 3D Printer), Fusetec is manufacturing a wide variety of medical models that solve all these problems.

Click read more to find out how medical models printed with Stratasys’ DAP is revolutionizing surgical training and planning.

“3D printing has really changed the way in which we train our surgeon.”

Prof. Peter John-Wormald,

Department Chair of Otolaryngology Head and Neck Surgery

Adelaide and Flinders Universities

|

|

This Month's Announcements

We have several product announcements to make this month:

- The multi-cartridge discount is going to end this year (place your orders now!)

- The J7-/8- series warranty upgrades and multi-pack head sale will end by next February

- Stratasys’ commitment of the shelf life of PolyJet materials, respectively to direct partners and customers

- Windows 7 will no longer support Stratasys software after January 14. 2020 and what to do next

Please note all these changes and we will appreciate it if you share them with stakeholders at your respective company.

|

|

GrabCAD Compatibility Updates

Please note that support for Stratasys software on Windows 7 platform is ending as of January 14, 2020. For more details, please refer to the table below.

| Stratasys Software Product | Details of Windows 7 Support | Action to Take |

| GrabCAD Print | GrabCAD Print 1.37 (scheduled for 12/17/19) will be the final release supported on Windows 7. Stratasys will stop providing software updates for GrabCAD Print on Windows 7, will no longer ensure GrabCAD Print works on Windows 7, and will not offer support for operational issues involving Windows 7 after GrabCAD Print 1.37 and after January 14, 2020. | Upgrade PC’s running GrabCAD Print to a supported operating system. More details |

| Insight & Control Center | Stratasys will no longer ensure that Insight and Control Center work with Windows 7 and will not offer support for operational issues involving Windows 7. | Upgrade PC’s running Insight or Control Center to a supported operating system. More details |

| GrabCAD PolyJet Job Manager | Stratasys plans to stop support for PolyJet Job Manager on Windows 7. | More recommendations soon. |

| PolyJet Host PC’s (aka. Embedded Computers) for Connex 3 PrintersJ-Series Printers | Stratasys plans to stop support for Windows 7 on the host PC’s of PolyJet printers. | More recommendations soon. |

|

|

Shelf Life Commitment of PolyJet Materials

| Material | To Direct Customers Min. Shelf-Life for Delivery | To Partners Min. Shelf-Life for Delivery |

| PolyJet Materials* (*except as otherwise noted) |

6 months | 8 months |

| Hearing Aid Family* Materials (*where applicable) | 4 months | 5 months |

| Agilus30™ Family Material | 4 months | 5 months |

| VeroUltraClear™ Component | 4 months | 5 months |

| TissueMatrix™ | 4 months | 5 months |

| GelMatrix™ | 3 months | 4 months |

|

|

|

|

|

|

|

|

End of Sale: J7/8 Series Warranty Upgrades & Multi-Pack Heads

|

|

Miscellaneous J7/8 series PN#s will no long be sold after March 1st, 2020.

|

|

| PN | Description |

| WNT-UG0038 | 3Y - Partner Warranty Upgrade to Diamond Care Level, Stratasys J750/J850 |

| WNT-UG0039 | 1Y - Partner Warranty Upgrade to Diamond Care Level, Stratasys J750/J735/J850/J835 |

| WNT-UG0019 | 3Y - Warranty Upgrade to Diamond Care Level, Stratasys J750/J850 |

| WNT-UG0020 | 1Y - Warranty Upgrade to Diamond Care Level, Stratasys J750/J735/J850/J835 |

| WNT-UG0062 | 3Y - WARRANTY UPGRADE TO DIAMOND CARE LEVEL, STRATASYS J735/J835 |

| WNT-UG0063 | 3Y - PARTNER WARRANTY UPGRADE TO DIAMOND CARE LEVEL, STRATASYS J735/J835 |

|

|

|

|

PolyJet multi-print head packs will no long be sold after March 1st, 2020.

| PN | Description |

| KIT-02021-S | 4 SHR PACKS (PolyJet Print Heads) |

| KIT-02022-S | 7 SHR PACKS (PolyJet Print Heads) |

|

|

|

|

|

|

Multi-Cartridge Discount Expiration

We have been offering multi-pack discounts on cartridges to encourage “bulk orders” (4% discount on quantities of 4 or more). Yet, the bulk orders from partners are significantly higher, and resellers are often confused about the prices when 4 vs 5 or 8 vs 11 cartridges. Furthermore, this discount is not applicable to over 80% of the orders.

As a result, we will terminate this discount soon: the last day of discount is January 31, 2020, and starting from February 1, 2020, all cartridges will be sold at standard prices. If you have any questions, please reach out to [email protected].

|

|

|

|

Figurine: A New Hot Application

There has been a steady increase in 3D printed figurines around the world, and we have more and more opportunities that are related to the figurine industry in our funnel. It has been noticed that many customers who have Z-Corp (CJP) are hoping to upgrade their systems.

The following are the two reasons why it is worth our efforts to focus on the figurine manufacturers. First, each account may purchase multiple printers, after they are made aware of the value that our technologies can deliver. Second, figurine manufacturers tend to produce 24/7, which means an extremely high consumption of materials.

Schiner 3D Repro has been using J750 to bring ultra-realistic, first-of-its-kind 3D printed snow globes to life and reduced the production time by as much as 85% (for both one-off customized and large orders). The layer thickness of those models is as fine as 0.014mm; the colors are vivid, and the PolyJet materials are stable over the time.

“the precise edges, vivid color definition and smooth surface finish achievable with the J750 are vital to ensuring the high-end standard our customers are looking for.”

JÖRN-HENRIK STEIN, CEO OF SCHINER

You may download the Schiner case study. More success stories on manufacturing from local customers will be released in the next few months.

|

|

|

|

© Stratasys 2015-2019. All rights reserved

Confidential: Do not forward to anyone outside the company.

Stratasys is ISO 9001:2008

Certified CONFIDENTIALITY NOTICE: This message, including any attachments, is the property of Stratasys and is solely for the use of the individual or entity intended to receive it. It may contain Stratasys confidential, proprietary and/or privileged information, and any unauthorized review, use, disclosure or distribution is prohibited. If you are not the intended recipient or if you have received this message in error, please permanently delete it and contact the sender by reply e-mail.

|

|